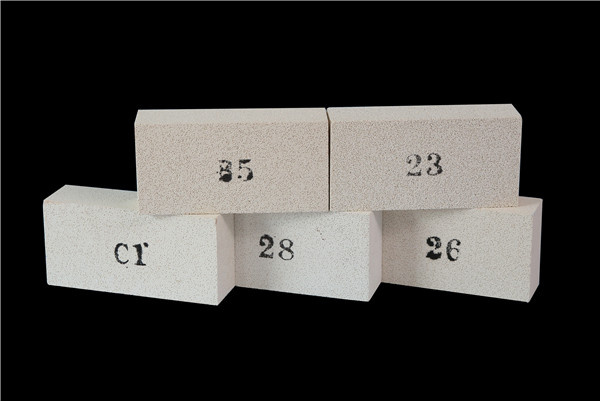

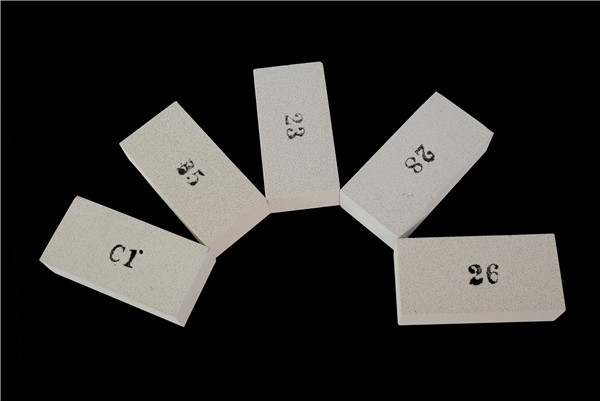

Mullite lub teeb-hnyav rwb thaiv tsev cib

Product Description

Lub teeb yuag mullite cib muaj qhov porosity siab, uas tuaj yeem txuag tau cua sov ntau dua thiab yog li txo cov nqi roj.Meanwhile lub teeb yuag txhais tau hais tias tsawg dua tshav kub cia muaj peev xwm, yog li tsawg lub sij hawm yuav tsum tau thaum lub kiln yog rhuab los yog txias.Lub sijhawm ua haujlwm nrawm dua tuaj yeem ua haujlwm tau.

Nws tuaj yeem siv rau ntawm qhov kub ntawm 900 txog 1600 ℃.

Nws yog tsuas yog siv los ua kiln hauv qhov kub thiab txias (tsawg dua 1700 ℃) kilns ntawm ceramics, petrochemical, metallurgy thiab machinery.

Tej yam ntxwv

Tsawg thermal conductivity, tsis muaj cua sov muaj peev xwm, tsis muaj impurity cov ntsiab lus

Lub zog muaj zog, zoo heev thermal shock kuj, yaig kuj

Qhov tseeb qhov ntev

Daim ntawv thov

Ceramics cov menyuam kiln thiab shuttle kiln: txheem cib, cov menyuam hla qhov cib, hanger cib,

Kev lag luam metallurgy: kub moj tej tawg rauv;sab hauv hauv ob sab phlu ntawm foundry kilns

Kev lag luam fais fab: lub zog tsim hluav taws xob thiab cov khoom siv txaj fluidised

Electrolytic Aluminium kev lag luam: kiln hauv ob sab phlu

Yam khoom yam ntxwv

| Mullite lub teeb-hnyav rwb thaiv tsev cib Khoom Khoom | ||||||

| Khoom Code | MYJM-23 | MYJM-26 | ZWM-28 | ZWM-30 | ZWM-32 | |

| Kev ntsuas kub (℃) | 1260 | 1400 | 1500 | 1550 | 1600 | |

| Qhov ceev (g / cm³) | 550 | 800 | 900 | 1000 | 1100 | |

| Permanent linear thrinkage (℃ × 8h) | 0.3 (1260) | 0.4 (1400) | 0.6 (1500) | 0.6 (1550) | 0.6 (1600) | |

| compressive zog (Mpa) | 1.1 | 1.9 | 2.5 | 2.8 | 3 | |

| Repture zog (Mpa) | 0.8 ua | 1.2 | 1.4 | 1.6 | 1.8 | |

| Thermal conductivity (W / mk) (350 ℃) | 0.15 | 0.26 | 0.33 ib | 0.38 ib | 0.43 ib | |

| Tshuaj muaj pes tsawg leeg (%) | Al2O3 | 40 | 54 | 62 | 74 | 80 |

| Fe2O 3 | 1.2 | 0.9 | 0.8 ua | 0.7 ua | 0.5 | |

| Nco tseg: Cov ntaub ntawv kuaj pom yog cov txiaj ntsig nruab nrab ntawm cov kev sim ua raws li cov txheej txheem txheej txheem thiab muaj kev hloov pauv.Cov txiaj ntsig yuav tsum tsis txhob siv rau cov laj thawj tshwj xeeb.Cov khoom lag luam tau ua raws li ASTM C892. | ||||||